5 Features of Bandsaw Blades

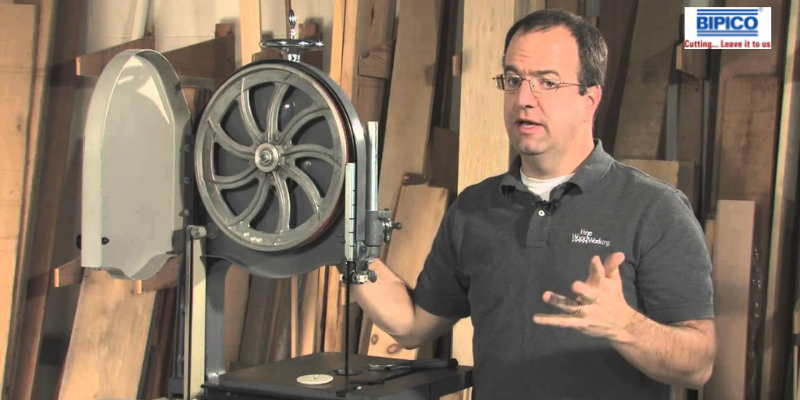

The bandsaw is without a doubt one of the most practical and adaptable tools a woodworker can own. This is mostly because it can cut curved and straight lines and deep sections. A bandsaw is a vital tool that requires little floor space and has access to a wide variety of blades. The bandsaw is the most adaptable tool in the shop since it can rip, cross-cut, resaw, and cut wafer-thin veneers, tenon cheeks, bevels, curves, and even circles.

Making the ideal choice can be challenging because BIPICO provides so many different machines. Each user has their own unique set of needs, therefore one machine can be better suited than another. A bandsaw with a high fence, a sizable depth of cut, and a strong engine may be required for a furniture maker. must be appropriate for jobs like resawing or cutting veneers. When turning bowl blanks, it may be preferable for the turner to use a narrow blade because it is easier to fit and track. A sturdy table with a suitable breadth and strong blade guides to resist sideways pressure is also important.

Important aspects of bandsaw design

Band Wheels

The mechanism by which the motor's power is transferred to the blade is the band wheels. To reduce vibration, wheels should be well balanced. To ensure precise blade tracking, a high-quality tire must be used.

Cast alloy wheels on smaller or hobby-rated machines are typically balanced by hand.

increased capacity Trade or industrial bandsaws have cast or alloy wheels that are dynamically balanced and produced utilizing high-tech industrial technology.

Cast iron wheels' "flywheel effect" enhances cutting effectiveness while attenuating vibration. Additionally, they can better handle the tensioning stresses generated by larger blades.

Frames

Steel sheet is folded and welded to create the frames of all modern bandsaws. In order to endure the forces brought on when the blade is tensioned, this creates an incredibly robust and rigid framework. If the frame needed to be more sturdy, it would flex under pressure and pull the top and bottom band wheel boxes together.

Many of the larger BIPICO machines have vertical spines that are triangular in section, making them exceedingly sturdy, and the bandsaw boxes have additional webbing to boost their rigidity and strength. Additionally, compared to the Hobby line, the Trade and Industrial machines' steel gauge is substantially thicker.

Tensioning the blade

Unquestionably, this is among the most crucial features of any bandsaw. The saw won't be able to continuously generate straight and uniform cuts if the blade is not correctly tensioned.

The spring tightens the blade, and when it is tensioned, the blade can withstand a tensile strain of up to 20,000 psi.

If utilizing a bi-metal blade, which is substantially stronger than "stock" blades, this can reach 30,000 psi. The machine's frame needs to be sufficiently sturdy to withstand this stress without warping.

Tables

From the smallest hobby saws to the largest industrial saws, all BIPICO bandsaw tables are constructed of cast iron. In addition to offering a flat, smooth surface, this material's substantial mass also serves to dampen vibrations during use. All tables are supported by sturdy trunnions and have a tilt range of -5 to +45 degrees. Because of the trunnions, the blade can be tilted and adjusted to any angle up to 45 degrees, ensuring that it is readily placed at 90 degrees to the table surface. The largest industrial models contain a handwheel-operated rack and pinion mechanism to adjust the table, making it possible to precisely control the angle even with one hand!

Blade guides

The blade guides' primary function is to keep the blade from twisting while making a cut. Except for the entry-level Hobby Series, all BIPICO bandsaws feature a pair of high-quality ball-bearing blade guides above and below the table.

These are easily adjustable so that they only barely touch the blade.

There will also be a transverse thrust race bearing at the back of the blade, both above and below the table. This needs to be adjusted such that it is separated from the blade by a thick piece of paper. When a thicker or thinner blade is installed in the bandsaw, the ball-bearing guides will also need to be modified.

Summary:

A bandsaw is an essential tool in every woodworking shop, and some would argue that it is the first machine you should buy. When purchasing one, think about the jobs you'll be doing as well as how much you'll be using it, and then match them to these attributes to get the best saw for you.

Comments

Post a Comment