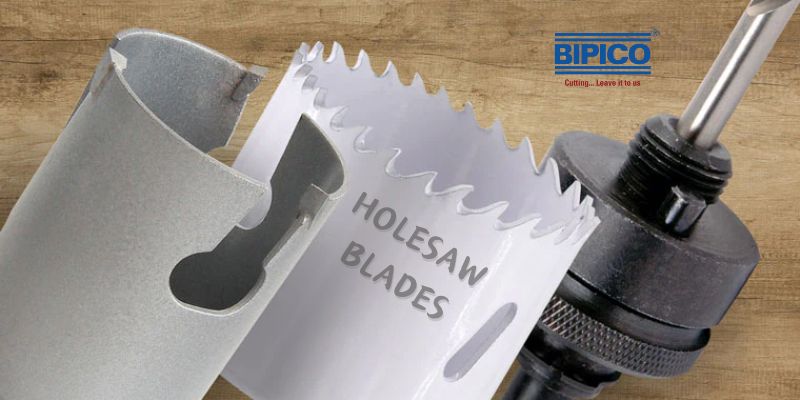

A Comprehensive Guide to Choosing the Right Holesaw Blades for Your Projects

Holesaw blades are essential for cutting precise holes in wood, metal, plastic, and drywall. Choosing the right holesaw blade for your project is crucial for achieving accurate and clean cuts. This comprehensive guide will explore the factors to consider when selecting the appropriate holesaw blades for your needs. 1. Understand Your Project Requirements: Before selecting a holesaw blade, it is essential to understand the requirements of your project. Consider the following factors: Material: Determine the type of material you will be cutting, whether it is wood, metal, plastic, or another substance. Size of the Hole: Decide on the hole diameter you must cut. Holesaw blades come in various sizes to accommodate different hole diameters. Depth of Cut: Consider the depth of the hole you need to cut. Some projects may require a shallow cut, while others require a deeper one. 2. Consider Tooth Configuration: Holesaw blades come with different tooth configurations, which affect the cuttin...