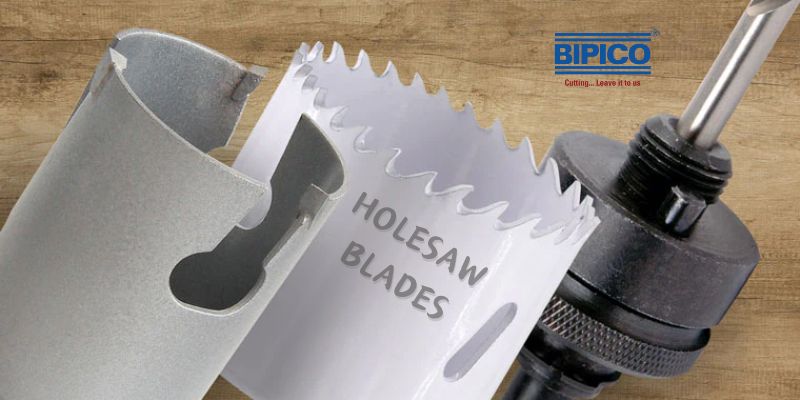

A Comprehensive Guide to Choosing the Right Holesaw Blades for Your Projects

1. Understand Your Project Requirements:

Before selecting a holesaw blade, it is essential to understand the requirements of your project. Consider the following factors:

- Material: Determine the type of material you will be cutting, whether it is wood, metal, plastic, or another substance.

- Size of the Hole: Decide on the hole diameter you must cut. Holesaw blades come in various sizes to accommodate different hole diameters.

- Depth of Cut: Consider the depth of the hole you need to cut. Some projects may require a shallow cut, while others require a deeper one.

2. Consider Tooth Configuration:

Holesaw blades come with different tooth configurations, which affect the cutting speed, efficiency, and finish. Common tooth configurations include:

- Variable Pitch: Provides faster and smoother cutting by varying the tooth spacing.

- Standard Pitch: Offers a balance between cutting speed and smoothness.

- Gulleted Teeth: Designed for efficient chip removal, reducing heat buildup, and prolonging blade life.

3. Choose the Right Blade Material:

The material of the holesaw blade determines its durability, cutting efficiency, and suitability for specific materials. Common materials for holesaw blades include:

- High-Speed Steel (HSS): Suitable for cutting wood, plastic, and thin metal sheets.

- Bi-Metal: Combines HSS and a softer steel body, offering durability and flexibility for cutting through tougher materials like stainless steel and cast iron.

- Carbide-Tipped: Ideal for cutting hard materials like ceramic, porcelain, and abrasive materials.

4. Evaluate the Shank Design:

The shank design of the holesaw blade determines its compatibility with different power tools. Ensure that the shank diameter matches the chuck size of your drill or holesaw arbours.

Look for additional features:

- Depth Control: Some holesaw blades have depth control features, allowing you to adjust the cutting depth for precise results.

- Pilot Drill Bit: Many holesaw blades include a pilot drill bit that helps center the blade and stabilise the cutting process.

- Ejection Spring: Ejection springs facilitate easy removal of the cut material from the holesaw blade.

5. Consider Safety Precautions:

- Wear appropriate personal protective equipment, including safety glasses, gloves, and ear protection, when using holesaw blades.

- Follow the manufacturer's instructions and recommended operating speeds to prevent accidents and ensure optimal cutting performance.

6. Assess Budget and Longevity:

- Consider your budget constraints when selecting a holesaw blade. While higher-quality blades may come with a higher initial cost, they often offer better durability and longevity, resulting in cost savings over time.

- Evaluate the expected lifespan of the blade based on its material, construction, and intended use. Investing in a durable blade may be more cost-effective in the long run, especially for frequent or demanding cutting tasks.

7. Explore Specialty Blades for Unique Applications:

- Certain projects may require specialised holesaw blades designed for specific applications. For example, diamond-coated holesaw blades are suitable for cutting through hard materials like glass, tile, and stone.

- Explore speciality blades with unique features such as diamond grit, tooth geometry, or coatings tailored to your project requirements for enhanced performance and precision.

8. Consider Compatibility with Accessories and Attachments:

- Check the compatibility of the holesaw blade with various accessories and attachments, such as extension rods, arbours, and centring guides. Compatible accessories can enhance the versatility and functionality of your holesaw setup, allowing you to tackle a wider range of projects effectively.

- Ensure that the holesaw blade and accompanying accessories are compatible with your existing power tools and equipment to avoid compatibility issues and ensure seamless integration.

9. Seek Recommendations and Reviews:

- Research and seek recommendations from professionals, industry experts, and fellow DIY enthusiasts regarding the best holesaw blades for your specific applications and materials.

- Read reviews and testimonials from users with experience with the holesaw blades you are considering. Pay attention to performance, durability, and overall satisfaction feedback to make informed purchasing decisions.

Conclusion:

Choosing the right holesaw blade is essential for achieving precise and efficient cuts in various materials. By considering factors such as material, blade material, tooth configuration, shank design, and additional features, you can select the most suitable holesaw blade for your project requirements. Remember to prioritise safety and follow best practices for using holesaw blades to ensure a successful and safe cutting experience.

Comments

Post a Comment