Top Benefits of Using Bi-Metal Bandsaw Blades for Industrial Applications

In industrial settings, the right metal cutting tools can make all the difference in achieving efficiency, precision, and cost savings. Bi-metal bandsaw blades are a prime example of an advanced solution that meets these demands. Constructed by welding high-speed steel teeth onto a flexible alloy steel back, these blades combine the durability of high-speed steel with the flexibility of alloy steel, making them ideal for cutting a wide variety of materials in high-demand environments. The result is a metal cutting tool that offers superior performance, longevity, and versatility for various industrial applications, from metalworking to wood and plastics.

Using bi-metal bandsaw blades provides numerous advantages that help businesses streamline their operations. Their resistance to wear and heat allows them to cut through tough materials without losing their edge, reducing downtime and maintenance costs. The flexible design minimises breakage, ensuring consistent cutting performance even in challenging conditions. Moreover, bi-metal blades can deliver high-precision cuts, making them perfect for industries that require accurate and smooth results. In this blog, we will explore the benefits of using bi-metal bandsaw blades for industrial applications and why they are the preferred choice for many professionals.

Bi-metal bandsaw blades have become a top choice in industrial applications due to their remarkable performance and versatility.

Here are ten key benefits that make bi-metal blades an essential tool for a wide range of industries:

1. Superior Durability and Longevity

Bi-metal bandsaw blades are known for their exceptional durability, which makes them ideal for demanding industrial tasks.

The high-speed steel teeth maintain sharpness for longer periods.

The alloy steel back provides flexibility and resistance to breaking.

Reduced frequency of blade replacements helps lower operating costs.

2. Cost-Effectiveness Over Time

Although bi-metal blades may have a higher initial cost, they offer long-term savings due to their extended lifespan.

Fewer replacements mean lower overall tool costs.

Reduced maintenance needs to keep downtime to a minimum.

Enhanced performance leads to better production efficiency.

3. High Cutting Precision

Clean, smooth edges reduce the need for post-processing.

Minimises material waste due to precise cutting.

Ideal for applications requiring tight tolerances, such as metalworking.

4. Versatility in Material Cutting

These blades are incredibly versatile and capable of cutting through a wide range of materials without compromising performance.

Suitable for cutting metals, plastics, and even wood.

Can handle tough materials like stainless steel, titanium, and alloys.

Effective in both thick and thin materials, offering diverse applications.

5. Improved Cutting Speed

Bi-metal bandsaw blades offer fast cutting speeds, increasing productivity in industrial operations.

The ability to cut through materials quicker reduces overall production time.

High-speed cutting helps meet high-demand deadlines and specifications.

Designed to perform well in both continuous and intermittent cutting tasks.

6. Heat Resistance

Bi-metal bandsaw blades are engineered to withstand extreme temperatures generated during high-speed cutting.

High-speed steel teeth can handle elevated temperatures without losing sharpness.

Reduces the risk of overheating and blade fatigue during prolonged cutting.

Helps maintain consistent cutting performance even under high heat conditions.

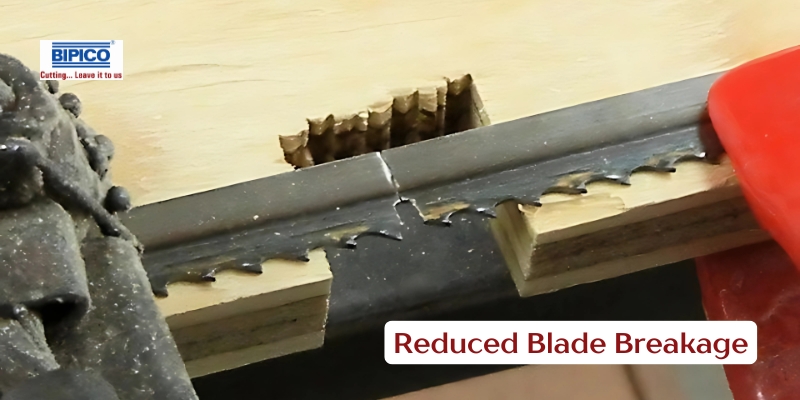

7. Reduced Blade Breakage

The flexible back material absorbs shock and vibration.

Ideal for heavy-duty applications where other blades might fail.

Provides a safer cutting environment by reducing the likelihood of accidents.

8. Improved Surface Finish

Bi-metal blades provide smoother, cleaner cuts, essential for industries requiring high-quality finishes.

Ideal for applications that require a smooth surface with minimal burrs.

Reduces the need for additional finishing processes, such as grinding.

Results in higher-quality finished products, especially for precision parts.

9. Consistent Performance

One of the key benefits of bi-metal blades is their ability to maintain consistent performance throughout their lifespan.

Reliable cutting performance from start to finish.

The blade teeth maintain their integrity over time, providing consistent results.

Ideal for high-volume production where uniformity is crucial.

10. Minimal Vibration and Noise

Bi-metal bandsaw blades are designed to reduce vibration and noise, enhancing operator comfort and cutting efficiency.

Less vibration ensures smoother cutting and reduces strain on the machinery.

Quieter operation creates a more comfortable working environment for operators.

Helps extend the lifespan of the machine by minimising stress on components.

Comments

Post a Comment