Different Types Of Cutting Blades And Their Uses

The metal cutting industry is growing at a fast pace and advancing with every passing day. The metal cutting and manufacturing units are enhancing the quality of the work and productivity by embracing the right cutting tools for various operations. When you are making use of the right tools, it becomes easier for the workers to improve the level of productivity and maintain precision in the work.

The important thing to note here is to know about different cutting blades and choose the best cutting blade for a specific project. You may think that selecting the right cutting blade is simple and convenient. But it is easier said than done. You need to consider a lot of factors when you are selecting the cutting blade.

The first thing that will come to your mind when selecting the blade is the structure of the machine and the type of cut you want to achieve. Based on these factors, you can ensure that you are picking the best cutting blade. Besides this, you will have to ensure the width of the blade and what material you will be cutting with the blade. This will help you know the teeth per inch required to achieve the best result. Once you are clear with all the requirements, you will understand everything about cutting blades.

Through this informative article, you will get to know about different types of cutting blades.

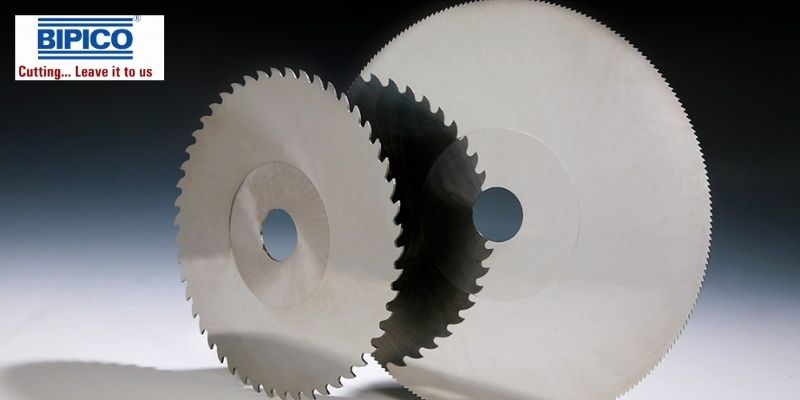

What Do We Mean By A Cutting Blade?

A cutting blade is a tool that is fixed to other machines to achieve different types of cuts in a wide range of materials. We will learn more about the band saw blades.

What Do We Mean By A Band Saw Blade?

The metal cutting industry makes use of the band saw blades to achieve curvy cuts in the material. The band saw blades can be used for a wide range of materials, including metallic objects and wood. In the case of metallic material, the band saw blade is good for ferrous and non-ferrous material. Usually, the metal cutting industry employs band saw blades for optimizing objects with irregular shapes. You get smooth, accurate, and precise cuts with the bandsaw blades. A bandsaw blade is a cutting blade that is versatile and has numerous applications in metal cutting/ manufacturing units.

Bi-Metal or Carbide: Which Bandsaw Metal Will Be Useful For Which Task?

When you want to use a bandsaw blade for a particular task, it is essential to choose the best one to achieve great results. In the market, you can avail bi-metal and carbide-tipped bandsaw blades. This will make it difficult for you to select the right cutting blade for the job.

Bi-Metal Blades: Understanding Bi-Metal Bandsaw Blades

When you decide to work with the bi-metal bandsaw blades, you need to check certain parameters. Bi-metals are used for cutting heavy and strong objects that have a spring backing, flexibility, and perfect resistance. You can employ bi-metal bandsaw blades for cutting a wide range of metals such as stainless steel pipes, carbon steel, structural steel, angles, tool steel, and many other objects.

Carbide-Tipped Cutting Blades

Now, let’s understand different cutting blades based on their TPI—Tooth Per Inch.

Regular-tooth Blades

When you are discussing different types of blades, regular-tooth cutting blades are most common. These blades have straight teeth and perfect rakes. Such types of blades are useful for enhancing the cuts through contour sawing. You can use it for a wide range of wooden materials.

Hook-tooth Blades

This cutting blade is similar to that of regular-tooth blades. The teeth have deep gullets and are large. You can use this blade to develop coarse cuts in metallic objects, wood plastic, and even hardwood. The blade will remove all the debris and provide a precise cut.

Skip-tooth Blades

Skip tooth cutting blades have a slightly different design, as they have shallow gullets and wide-spacing teeth. Besides, it has a zero rake angle, with all the teeth forming a 90-degree angle. This cutting tool is applicable in cutting a wide range of wooden objects and non-ferrous materials.

Blades For General Purpose

Summary:

No matter what your cutting requirements are, contact Bipico for the top-notch industrial blades. If you are not sure which blade will best suit your requirements, reach out to our technical team, and we shall guide you according to your cutting needs.

Comments

Post a Comment