What Are the Benefits and Application of Bandsaw Blade?

Bandsaw blades have been an essential tool in the woodworking industry for decades, and their applications have only expanded over time. The blade's unique design and versatility have made it a popular choice for professionals and DIY enthusiasts. Not only can bandsaw blades make straight cuts in wood, but they can also be used for curved or intricate cuts on various materials. In this blog post, we will delve into the benefits and the different applications of bandsaw blades that have made them a staple in the woodworking world.

Whether you are a professional carpenter, woodworker, or DIY enthusiast, understanding the advantages of a bandsaw blade will help you achieve precision cuts and enhance your overall efficiency. With a range of blade sizes and types available, it is important to understand the different applications of each blade and how they can be used for specific woodworking projects. Furthermore, we will discuss how the bandsaw blade's unique design and composition make it an ideal tool for cutting various materials.

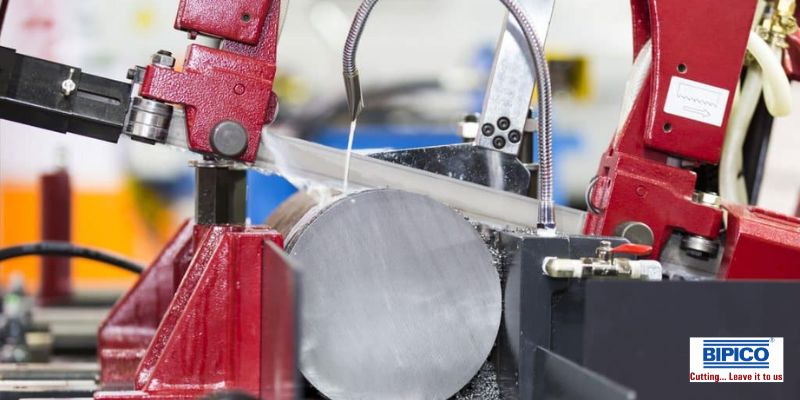

Precision Cutting: Bandsaw blades are known for making precise cuts through various materials, including wood, metal, plastic, and meat. The blade's design allows for accurate and straight cuts, making them ideal for tasks that require precision and accuracy. Bandsaw blades are commonly used in woodworking shops to create intricate designs or easily cut thick pieces of lumber. They can also be used in metalworking to cut through thick metal sheets or create intricate metal designs.

Efficiency: Bandsaw blades are highly efficient cutting tools that make quick and clean cuts through materials. Unlike traditional saws, bandsaw blades use a continuous loop of teeth to make the cut, which means less resistance and friction during the cutting process. This not only makes the cutting process faster but also helps prolong the blade's life. Bandsaw blades are often used in manufacturing facilities for cutting large quantities of material quickly and efficiently, such as cutting logs into lumber or cutting metal sheets into specific sizes.

Versatility: Bandsaw blades come in different widths, tooth patterns, and materials, which makes them highly versatile cutting tools. For instance, blades with smaller teeth and narrow widths can cut intricate designs in thin materials such as plywood and plastic. In comparison, blades with larger teeth and a wider width are ideal for cutting thicker materials such as hardwood and metal. Additionally, some bandsaw blades are made of carbide. This durable and wear-resistant material can withstand high temperatures and friction, making them suitable for cutting hard materials such as stainless steel and titanium.

Safety: Bandsaw blades are generally safer to use than other saws. The blade is fully enclosed in a frame, which minimizes the risk of injury from contact with the blade. Additionally, the blade's cutting action is slower than that of other saws, making it easier to control and less likely to kick back. Bandsaws also have blade guards, blade tensioners, and blade tracking systems that help ensure safe operation.

Cost-effective: Bandsaw blades are cost-effective cutting tools that can help you save money in the long run. Unlike other saws requiring frequent blade replacements, bandsaw blades can last long with proper maintenance. Additionally, bandsaw blades can cut through various materials, which means you can use one blade for multiple tasks, reducing the need to buy different types of saws for different materials.

Eco-Friendly: Bandsaw blades are an eco-friendly cutting tool that generates less waste than other saws. The cutting process produces smaller kerf (the thickness of the material that is removed during cutting), which means that there is less waste material. Additionally, bandsaw blades can be easily resharpened, which helps to extend their life and reduce the need for blade replacements. This saves you money and reduces the amount of waste generated.

The Applications of Bandsaw Blades

Woodworking: Bandsaw blades are widely used in woodworking shops to cut and shape different types of wood. They are ideal for making intricate cuts, curved shapes, and resawing (cutting a thick board into thinner pieces). Woodworkers can use a variety of bandsaw blades to achieve different results, from fine-toothed blades for intricate work to wider blades for resawing.

Metalworking: Bandsaw blades are also popular in metalworking shops, where they are used to cut different types of metal, including Aluminium, brass, and steel. Metal bandsaw blades are designed to withstand the heat of cutting metal and are available in various widths and tooth patterns. They are ideal for cutting thin sheets of metal, solid bars, and pipes.

Food Processing: Bandsaw blades are widely used in the food processing industry for cutting meat, fish, and poultry. The blades are designed to meet the strict hygiene and safety standards required in the food industry. They are available in different widths and tooth patterns to suit different types of meat and cuts.

Manufacturing: Bandsaw blades are also commonly used in manufacturing facilities to cut different materials, including plastic, foam, and composites. They are ideal for cutting large quantities of material quickly and accurately, reducing the time and cost of production.

DIY projects: Bandsaw blades are also popular among enthusiasts who use them for home improvement projects. From cutting PVC pipes to making picture frames, bandsaw blades are versatile cutting tools that can handle various tasks.

Summary

In conclusion, bandsaw blades are highly versatile cutting tools that find application in various industries, including woodworking, metalworking, food processing, manufacturing, and DIY projects. They are ideal for making precise cuts, reducing waste, and increasing efficiency.

Comments

Post a Comment